Research and Development

Our on-site laboratory, fluid handling facilities and experienced research engineers allow us to find the optimum design for your specific need.

We can guide you in the optimum selection of your equipment with our laboratory, fluid handling

facilities and experienced application engineers. We can find the optimum tank design, special

arrangements, such as anti-vortex baffles, risers, dip tubes, mounting structures, nozzle orientations

and the most economical vessel shape. Our customer design service and fluid mixing laboratory are

capable of producing a complete mixer design even if little or no data is available.

Constant research into the latest technologies and processes allow for us to provide enhanced efficiency

and product reliability. We use extensive computational fluid dynamics to virtually assess mixer

performance under a variety of conditions to aid the development of improved impeller design.

Our in-depth knowledge of varying fluid behaviours and containing vessels along with our experience and dedicated teams are perfectly positioned to maximize your process results.

Feel free to Contact

Us with any questions.

Mixtec believes in constant innovation. Our dedicated research and design teams are constantly improving existing systems as well as developing new products offerings.

Products and processes are constantly changing and Mixtec believes strongly in being a part of the design right from the start in order to be able to offer the best possible solution to any application.

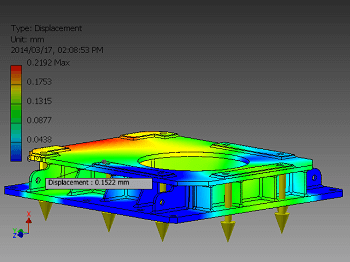

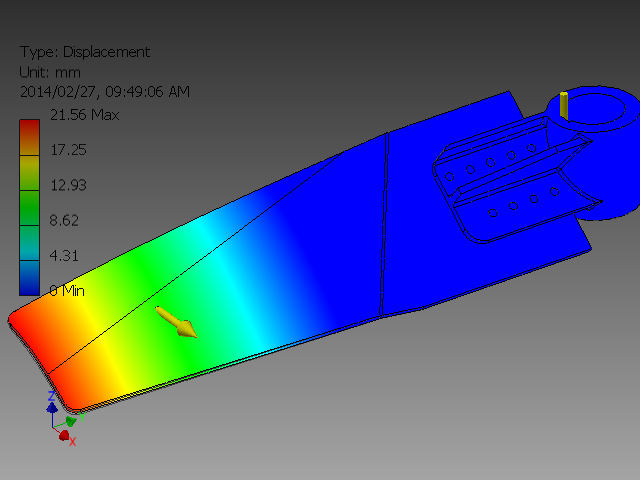

Mixtec uses 3D modelling software complete with FEA analysis when designing new products to ensure that all load factors are taken into consideration, providing the best possible life span of our products.

Based on computerized simulations, Mixtec will then produce an actual physical design for trials in our laboratory. Our research and design engineers then perform the required test work to prove the simulation's results.

With Mixtec Laboratories around the world, we are able to constantly test and improve our products as well as provide test work for more demanding and uncommon applications at the client’s request.

Having our own on-site laboratory allows us to constantly develop and test new impellers, their power numbers and their efficiency; enabling us to provide ever improving quality of service and more efficient designs to our customers.

With the ability to quickly assemble small scale versions of larger mixers in the field, we are able to test and analyse problems quickly and accurately, enabling us to respond to problems at a rate un-matched by our competitors.

Using computational fluid dynamics software, we are able to understand the flow characteristics generated by our impellers, which enables us to design a mixer that will perform adequately in any situation.

Computational fluid dynamics allows us to continue improving our extensive line of impellers and ensure that our impellers function properly in very specific mixer arrangements. Using computational fluid dynamics reduces the cost of research because expensive physical test models are not required. By keeping internal cost low we can pass the savings on to our customers.

Through the use of FEA we are able to refine as well as strengthen our designs to ensure longevity and provide our clients with the most trouble-free agitator possible. Mixtec is constantly improving it's products and will often custom design innovative solutions to our customers problems.

No two jobs are the same in the mixing industry, which is something Mixtec understands and supports. Mixtec will often design non-standard parts and equipment to better suit our clients application requirements, from building tanks, structures, baseplates and pedestals as well as even designing completely new impellers to clients specific process requirements.